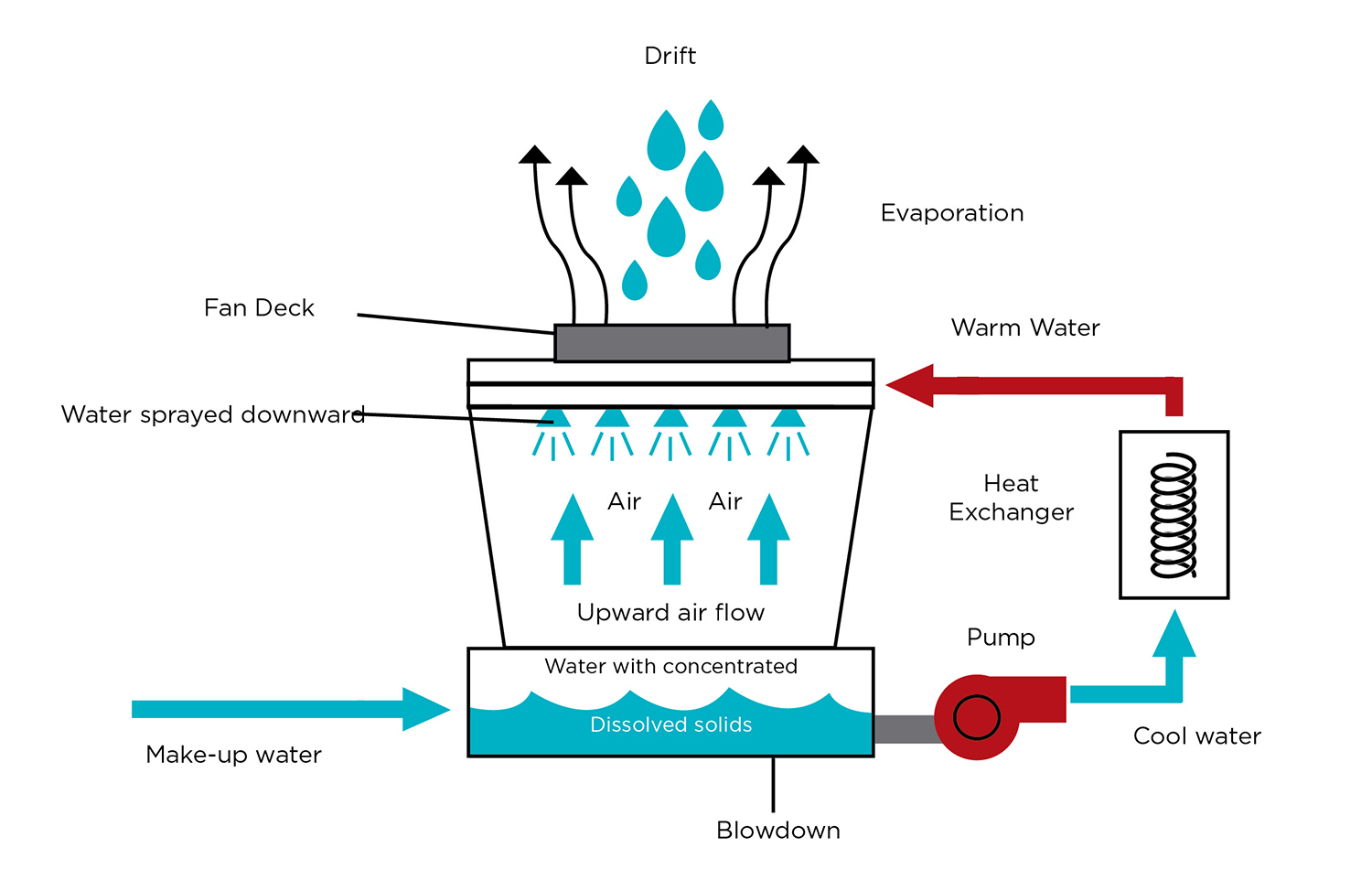

Mechanical draft towers utilise large fans to force or suck air through circulated water. These types of towers are used only by utility power stations. Due to the large size of these towers, they are generally used for water flow rates above 45,000m3/hr. Natural draft towers use very large concrete chimneys to introduce air through the media. The water exits the cooling tower and is sent back to the exchangers or to other units for further cooling.Ĭooling towers fall into two main categories: Natural draft and Mechanical draft. Hot water from heat exchangers is sent to the cooling tower. The make-up water source is used to replenish water lost to evaporation. They represent a relatively inexpensive and dependable means of removing low-grade heat from cooling water. The primary task of a cooling tower is to reject heat into the atmosphere. The dry and cool air from outside the tower will fall in, creating a constant cycle of air flow.Types and performance evaluation, efficient system operation, Flow control strategies and energy saving opportunities, Assessment of cooling towersĬooling towers are a very important part of many chemical plants. The warm and moist air is denser as compared to the cool air and therefore, it rises through the tower. Air movement takes place because of difference in density between the air that enters inside and the one that is already inside within the tower. Water getting cooled after heat transfer collected at basin or the bottom of the tower and hot/Warm and moist air get discharged from the top of the tower to the atmosphere. The hot water reject heat after contact with air and in that process fraction of water gets evaporated. Fresh air is induced at bottom of the tower and which then flows in the upward direction where heat transfer takes place between warm water coming from top and and cool air coming from lower side. The purpose of filling mater is to provides a more contact surface area for heat transfer.

CIRCULATED WATER DRIFT COOLING TOWER SERIES

The hot water inlet is connected to a series of nozzles also know as distributor with the help of which it get spray over the fill material evenly. Hot water that comes from the plant and is to be cooled pumped using pump to the top of the cooling tower which is considered as inlet of cooling tower or hot water inlet. Natural draft cooling tower works on natural convention to circulate the air completely through the tower. Classification of industrial cooling tower is described below There are different types of industrial cooling tower.

Hot water is sprayed from the top of cooling tower which exchange heat with the atmospheric air and results in reduction of temperature of hot water.Ĭonvection mode of heat transfer is used in the cooling tower are heat transfer takes place between air and water. Working principle of cooling tower – How does a cooling tower work?Ĭooling tower works on the principle of evaporation. It is used in industries to reduce temperature of water and thereby provide cooling water utility for the process. It rejects waste heat from the water and thereby reduces the temperature of water. Industrial cooling tower is a device which act as a heat rejection equipment. Working principle of cooling tower – How does a cooling tower work?.

0 kommentar(er)

0 kommentar(er)